Balaastiigga balaastikada iyo faakiyuumka

Sharax Gaaban:

Korontada iyo faakiyuumka waa laba geedi socod oo caam ah oo loogu darayo dahaarka birta qaybo balaastig ah. Nidaamkani wuxuu kordhin karaa caabbinta duugga ah iyo u adkaysiga daxalka qaybaha dusha sare, wuxuu kordhin karaa maqaarka macdanta iyo qurxinta muuqaalka.

Marka la barbardhigo rinjiga lagu buufinayo, electroplating balaastigga iyo faakiyuumka faakiyuunka ayaa leh caabbinta ugu wanaagsan ee ka caaggan, caabbinta daxalka iyo nuuradda birta ah ee gaarka ah. Waxaa caadi ahaan loo isticmaalaa qaybo ka mid ah alaabada dhamaadka-sare, sida guryaha wax soo saarka alaabooyinka kala duwan leh, kiisaska saacadaha casriga ah, badhamada, laambadaha haysta, laambadaha iyo qurxinta.

Mabaadi'da biyo-koronto siinta iyo goynta faakiyuhu way kala duwan yihiin, walxaha ku habboon iyo natiijooyinkuna way kala duwan yihiin. Aynu hoos ku soo bandhigno:

1. Electroplating caaga

Electroplating caaga ah waa geedi socodka lagu quusinaayo qaybaha balaastigga ee elektroolka iyo dhigida walxaha biraha ah dusha sare ee qeybta shaqada adoo ku shubaya falcelinta hadda ama kiimikada. Ka dib korantada, midabka dusha sare waa lacag, lacag hoosaad iyo cawl lacag ah.

Balaastikada 'ABS' waxaa horay loogu sii daayay habka kiimikada kiimikada ah ee naxaasta ah, kollaid palladium PD kiimikaad nickel toos ah u sameynta si ay u soo saarto lakab tabeysan oo leh isku xirnaan wanaagsan oo dusha sare ah, ka dibna biraha kale ayaa elektaroonig ah.

Electroplating waxaa lagu sameeyaa xalka biyaha elektiroolka, sidaas darteed waxaa loogu yeeraa "electroplating water", "hydropower plating". Kuwa ugu caansan ayaa ah dahaadhka naxaasta ee dusha balaastigga, nikkel nijaasta, chromium trivalent, midabka qoriga, nikkel pearl iyo wixii la mid ah.

Aragti ahaan, dhammaan balaastigyada waa la koronto-dhigi karaa, laakiin xilligan oo keliya ABS, ABS + PC ayaa ah kuwa ugu guusha badan, laakiin ku-xirnaanta dahaadhka elektaroonigga ah ee balaastigga kale kuma qanacsana. Nidaamka koronto-dhalinta biyaha waa mid fudud oo uma baahnid in lagu buufiyo aaladda ka hor iyo ka dib dahaadhka. Dahaadhku wuxuu leeyahay dhejis wanaagsan, daahan qaro weyn iyo qiimo jaban.

2. Dahaarka faakiyuumka caagga ah (Jirka Uumiga Jirka-PVD)

Xakamaynta Vacuum inta badan waxaa ka mid ah uumi-baxa, xajinta iyo dahaadhka ion. Dhammaantood waxay dhigaan filimo kala duwan oo biraha iyo biraha aan ahayn birta dusheeda

qaybo ka mid ah by muxaadaro ama sputtering hoos vacuum. Sidan oo kale, daahan dusha sare ah oo dhuuban ayaa la heli karaa.

Dahaadhida Vacuum inta badan waxa ka mid ah dahaadhka uumiga ee faaruqinta, dahaadhida xaakada iyo dahaadhka ion. Dhammaantood waxaa loo isticmaalaa in lagu xareeyo biro kala duwan dusha sare ee qaybaha balaastigga iyada oo la marsiinayo ama lagu buufinayo xaaladaha faaruqinta.

Filimka aan birta ahayn, iyadoo loo marayo qaabkan wuxuu noqon karaa daahan dusha oo aad u khafiif ah, wuxuuna leeyahay faa iidooyinka ugu wanaagsan ee xawaaraha degdegga ah iyo isku dhejinta wanaagsan, laakiin qiimaha sidoo kale wuu ka sarreeyaa, guud ahaan waxaa loo isticmaalaa isbarbardhigga, daahan shaqeynaya oo loogu talagalay daaha dhamaadka-sare wax soo saarka.

Faakiyuum waxaa loo isticmaali karaa caaga sida ABS, PE, PP, PVC, PA, PC, PMMA, iwm. Daawooyinka khafiifka ah waxaa lagu heli karaa iyadoo la marinayo faakiyuumka.

Qalabka faakiyuumka lagu dahaadho waxaa lagu dhejin karaa biro kala duwan, sida aluminium, qalin, naxaas iyo dahab, kuwaas oo leh dhibic ka hooseysa marka loo eego siligga tungsten.

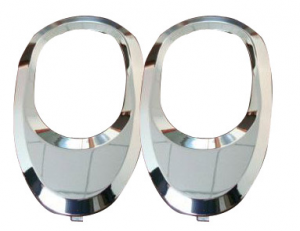

Automobile ABS qayb koronto

Qaybaha caaga ah ee leh koronto kuleylka 'nickle'

Qaybo balaastig ah oo koronto ku shaqeeya oo elektiroonig ah

Qaybo balaastik ah oo midabkeedu yahay dahab dhalaalaya oo sarreeya

3. Dahaarka faakiyuumka caagga ah (Jirka Uumiga Jirka-PVD)

Xakamaynta Vacuum inta badan waxaa ka mid ah uumi-baxa, xajinta iyo dahaadhka ion. Dhammaantood waxay dhigaan filimo kala duwan oo biraha iyo biraha aan ahayn birta dusheeda

qaybo ka mid ah by muxaadaro ama sputtering hoos vacuum. Sidan oo kale, daahan dusha sare ah oo dhuuban ayaa la heli karaa.

Dahaadhida Vacuum inta badan waxa ka mid ah dahaadhka uumiga ee faaruqinta, dahaadhida xaakada iyo dahaadhka ion. Dhammaantood waxaa loo isticmaalaa in lagu xareeyo biro kala duwan dusha sare ee qaybaha balaastigga iyada oo la marsiinayo ama lagu buufinayo xaaladaha faaruqinta.

Filimka aan birta ahayn, iyadoo loo marayo qaabkan wuxuu noqon karaa daahan dusha oo aad u khafiif ah, wuxuuna leeyahay faa iidooyinka ugu wanaagsan ee xawaaraha degdegga ah iyo isku dhejinta wanaagsan, laakiin qiimaha sidoo kale wuu ka sarreeyaa, guud ahaan waxaa loo isticmaalaa isbarbardhigga, daahan shaqeynaya oo loogu talagalay daaha dhamaadka-sare wax soo saarka.

Faakiyuum waxaa loo isticmaali karaa caaga sida ABS, PE, PP, PVC, PA, PC, PMMA, iwm. Daawooyinka khafiifka ah waxaa lagu heli karaa iyadoo la marinayo faakiyuumka.

Qalabka faakiyuumka lagu dahaadho waxaa lagu dhejin karaa biro kala duwan, sida aluminium, qalin, naxaas iyo dahab, kuwaas oo leh dhibic ka hooseysa marka loo eego siligga tungsten.

Qaybaha faleebada ee faleebada Lampshade

Faakiyuumka UV qaybo caag ah

Daawada faakiyuumka ee balaastigga ka muuqanaya koobka

Nano faakiyuumka dahaarka qaybo caag ah

Waa maxay farqiga u dhexeeya koronto-siinta balaastigga ah iyo bacda faakiyuumka?

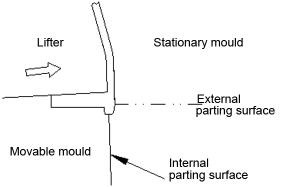

(1) Daawada faakiyuhu waa geedi socod lagu daboolayo xariiqinta xereynta iyo foornada faakiyuumka, halka electroplating ay tahay geeddi-socodka xalka biyaha. Sababtoo ah waxay buufinaysaa rinjiga, dahaarka faakiyuumku kuma haboona alaabada qaabka adag, halka electroplating biyaha aan lagu xadidayn qaabka.

(2) Tikniyoolajiyada farsamaynta, sida daaha faakiyuumka ee xabagta caagga ah, ayaa lagu soo koobi karaa si fudud: hoos u dhigga dusha aasaasiga ah, dedusting, roobab electrostatic, xereen UV Primer, daaweynta UV, faakiyuumka, faaruqinta, sagxadda dusha sare ee lagu buufiyo) , daaweynta, alaabada la dhammeeyay; dahaarka faakiyuumka ayaa ku xaddidan habka, mana ku habboon tahay in lagu farsameeyo alaabooyinka leh dhul aad u ballaaran shaqada darteed. Nidaamka farshaxanka si fiican looma xakameeyo, oo heerka cilladaha ayaa sarreeya.

Kala-bixinta elektaroonigga ah (guud ahaan ABS, PC / ABS): kiimikada ku sifeeya hawo-biyoodka hawo-yareynta yaraynta preimpregnation palladium dardargelinta korantada bilaa koleyga ah ee ku shaqeysa hydrochloric acid firfircoonida coke copper sulfuric acid firfircoonida nel nikkel niikel xiraya alaabada la dhammeeyo;

(3) Dahaarka korantada waxaa lagu dhammaystiri karaa wax soo saar si otomaatig ah u shaqeeya.

(4) illaa inta muuqaalka laga hadlayo, midabka dhalaalka filimka faakiyuumka loo yaqaan 'vacuum aluminized' ayaa ka iftiin badan kan electroplating chromium.

(5) Marka laga hadlayo waxqabadka, daboolka faakiyuumka balaastigga ah waa lakabka ugu dambeeya ee rinjiga, halka biyo-gelinta inta badan ay tahay chromium bir ah, sidaa darteed adkaanta birta ayaa ka sarreysa tan xabagta.

s iska caabin ah daxalka, daahan rinjiga sida caadiga ah waxaa loo isticmaalaa. Lakabka daboolku wuu ka fiican yahay lakabka birta, laakiin farqi yar ayaa u dhexeeya iyaga oo u baahan shuruudaha alaabada dhammaadka-sare leh; xaga cimilada, electroplating waxay kafiican tahay faleebada faakiyuumka, markaa waxay badanaa ubaahantahay adeegsiga banaanka ee muddada-dheer oo leh iska caabin cimilada.

In warshadaha baabuurta, waxaa sidoo kale jira shuruudo adag oo loogu talagalay iska caabinta heerkulka hoose ee sare, huurka iyo kuleylka, tirtirka dareeraha iyo wixii la mid ah.

(6) Dahaarka Vacuum waxaa badanaa loo isticmaalaa warshadaha isgaarsiinta elektiroonigga ah, sida qolofka taleefanka gacanta, codsiyada gawaarida, sida koobabka ka tarjumaya laambadaha baabuurta; dahaadhka biyaha waxaa badanaa loo isticmaalaa chromiumka qurxinta, sida jarista albaabka baabuurta. Albaabbada albaabka iyo wixii la mid ah.

(7) Marka la eego kala duwanaanta midabka muuqaalka muuqaalka, dahaarka faakiyuumku wuu ka qanisan yahay koronto-dhalinta. Daawada faakiyuumka ayaa laga samayn karaa dahab iyo dusha midabbada kale.

(8) illaa inta kharashka wax soo saarku uu khuseeyo, qiimaha goynta faakiyuumka hadda wuu ka sarreeyaa kan biyaha lagu dahaadhay.

(9) Daawada faakiyuhu waa geedi socod ilaalinta cagaaran oo cagaaran oo leh horumarin farsamo oo deg deg ah, halka korantada biyaha laga soo saaro ay tahay mid dhaqameed leh wasakh badan, warshadahana ay ku xaddidan yihiin saamaynta siyaasadaha qaran.

(10) Halkan waxaa ku yaal buufinta (falcelinta muraayadaha qalinka) oo hadda soo ifbaxay. Nidaamku waa nabaad-dhigis caag ah iyo deelectrostatic gaar ah aasaasiga dubista nano-ku buufinta dubista biyaha saafiga ah.

Tiknoolajiyaddani waxay sidoo kale saameyn ku yeelan kartaa muraayadda dusha caagga ah. Sidoo kale waa geedi socod ku habboon deegaanka. Hawlihii hore iyo kuwii dambe ayaa la mid ah dahaadhida faakiyuumka, laakiin keliya dahaadhka dhexe.

Aluminium waxaa lagu beddelay muraayad lacag lagu buufiyay, laakiin waxqabadka farsamo ee hadda socda ee hawshan lama barbar dhigi karo dahaarka biyaha iyo faakiyuumka. Waxaa kaliya lagu dabaqi karaa alaabada farsamada gacanta oo aan u baahnayn muuqaal sare iyo waxqabad.

Khadka wax soo saarka

Qalabka faleebada faakiyuumka ee qaybaha balaastigga ah

Line-soo-saarka electroplating caaga

Haddii alaab aad leedahay ay ku jiraan qaybo balaastiig ah oo koronto ku shaqeeya ama qaybo caag ah oo faakiyuum ah lagu buuxiyo fadlan nala soo xiriir